Science of Tatara and Japanese Sword

- Traditional Technology viewed from Modern Science -

Tatsuo INOUE

The traditional technology of tatara system, or Japanese steel making process, and Japanese sword are treated from the viewpoint of modern science, especially through the computer simulation of quenching of the sword. Discussions are made on the reason why such a traditional technology has been survived to be consistent with scientific rationality.

Key Words: Tatara, Japanese Sword, Traditional Technology, Modern Science, Computer Simulation

|

1. Introduction

The Japanese sword is now one of the typical traditional crafts of art, and so many monographs have been published in English as well as in Japanese. The sword is also interesting from the viewpoint of modern science and technology(1-18) since the way of making the sword is really consistent with science as same as other surviving traditional products.

Most Japanese swords are made of traditional Japanese steel called tamahagane, but not of modern steel, produced by tatara system by use of iron sand. The author has so enjoyed to devote himself to accumulate information on the scientific aspect on the Japanese sword and the tatara, and carried out some computer simulations during quenching of the sword(7-12) {See home page in web site;

http://force.energy.kyoto-u.ac.jp/~Inoue/jsword/jsword.htm

In the first part of this article, the author tries to show how to overview the swords followed by the material and forging process of Japanese sword with some comments. A special emphasis is placed on the computer simulation of quenching, or hardening, applied in the final stage of the manufacturing the sword from the viewpoint of continuum mechanics, which includes the modes of bending and the formation of blade simulated by a developed computer code " HEARTS"(19-22).

2. How to overview the tatara and Sword?

So many monographs on the swords have been published in English and other language as well as in Japanese, and recently in web sites. Among them, the site of Dr. L. Jones

http://www.aiusa.com/ medsword/

is so brilliant and interesting, from where we can link to almost many sites related to the sword and obtain so many kinds of information. There are many museums exhibiting swords. Readers are recommended to visit Wallace Collection, London,

http://www.the-wallace-collection.org.uk/

to see a lot of western medieval swords. The Japanese Sword Museum

http://www09.u-page.so-net.ne.jp/rj8/nbthk-tk/

in Tokyo is one of the specialized museum of the swords, and Wakou Museum

http://www.miraclewave.or.jp/yasugicity/alwakou.html

in Yasugi, Shimane, provides information of tatara, Japanese iron and steel making system. Metallurgical investigations of medieval western swords by Williams(13) are so interesting.

As for the Japanese swords, Tawara, a professor of Japanese Sword Research Laboratory, the University of Tokyo, accomplished a monumental work in the framework of metallurgy(9). Tawara measured the distribution of carbon density, precipitation and hardness in the cross section of the swords in relation to the pattern of blade and sori representing the mode of deformation during quenching. Successive works were made by Bain(2), Suzuki(3).

Very few works on the sword were made, however, from mechanical engineering aspect. Ishikawa(4) discussed the mechanism of cutting objects from theory of cutting and the shape of the sword from dynamics, and stress/deformation analysis after quenching by the finite element method was carried out by Fujiwara and Hanabusa(5,6) and the present authors(7-12).

3. Material, the tatara System

Due to the strength point of view, most surveying swords as weapons are made of steels, while copper and bronze swords were used for some purposes of decoration. As is well known, it is said that steels firstly appeared in Hittite at B.C.23 century. The technology to produce steel from iron ore were transported to Europe, Asia and other places in the world. The traditional steel in Japan is, on the other hand, normally comes from iron sand processed in the special way, called tatara system(1-3,14-18) (see Fig.1).

Fig.1 Old painting of tatara, traditional steel making system.

A popular Japanese animation movie "MONONOKE-HIME" treated the struggle of human being who cut trees used for the fuel of tatara against the guardian God of the forest.

The Iron and Steel Institute of Japan constructed an experimental system of tatara in 1969(14-17) in Sugaya, Shimane Prefecture, and accumulated interesting data of steel making technology. Due to the lack of the steel for the sword, the Nippon Bijutsu Token Hozon Kyokai, started to organize the tatara system in Torigami, Shimane Prefecture, under the cooperation with Hitachi Metals, Ltd. in 1977, and provides steel of 3-4 tons every year(3).

Iron sand with 2-5% content of iron mined from mountains, which includes the best quality of iron sand in Japan, concentrated to the degree of 60% by magnet system, while the mineral dressing method by gravity classification in flowing river, kanna nagashi, had been adopted, which is no more popular to prevent water pollution problem. Such enriched iron sand called masa satetsu contains 8% of pure iron Fe and iron oxide Fe2O3 with very small amount of impurity such as 0.026% phosphorus P and 0.002% sulfur S being injurious for carbon steels. Here, alumina Al2O3 is so rare to be beneficial for low temperature refinement to be stated later.

The enriched iron sand is supplied alternatively to the furnace with charcoal by hands. Figure 2 illustrates the cross sectional view of the furnace under operation with some drainage mechanism constructed to three meters under the ground. Only a difference of the system from the classical one in the figure is that electric motors are used for intermittent air blowing instead of manpowered bellows.

Fig.2 Cross section of tatara furnace.

Continuous burning is operated for 70h under the direction of a murage, or chief foreman. The temperature in the furnace is around 1200-1500°C lower than the melting point of the steel, which follows that the reduction process of the partly molten state is occurred between iron oxide Fe2O3 and silica SiO2 contained in the clay of furnace. During the process, the initial thickness of 200-400mm of the furnace is reduced to 50-100 mm. After taking out the slag from the bottom of the furnace followed by destroying the furnace, a block of blister steel called kera in sponge state with dimension of 2.7m in length, 1m in width and 200-300mm in thickness and with 2-2.5ton containing steel of 1.5-1.8ton is obtained, while necessary amount of iron sand and charcoal are respectively 8 and 13tons. (It is amazing that the block costs hundred thousand dollars, two hundred times expensive of normal steel!)

Steel produced on both sides of the block, where the enough deoxidization is completed by air supplied from kirokan (special wooden pipes) is called tamahagane, or noble steel, which is spelled as mother of metal in Japanese character. Other parts of the block with different chemical composition are also used for the sword making.

The chemical compositions of the best part of steel are 1.0-1.4% C, 0.02-0.03% P, 0.006% S, and 0.003-0.004% Ti, being very rare of sulfur and phosphorus even compared with industrial carbon steel. The steel is cooled by cold environment since the operation is carried out in the mid-winter followed by shearing, and distributed to approximately 300 professional sword smiths in Japan.

4. Manufacturing of Japanese Sword

The successive process of making a sword is illustrated in Fig.3.

Fig. 3 Illustration of manufacturing process of Japanese sword.

The smith makes a flat plate with a handle termed as tekoita, on which the small pieces of broken flat pieces are piled up covered by a special Japanese paper dampened by water containing clay and rice straws to prevent oxidation on the surface of steel by insulating air. It is known that SiO2 in the clay contributes to increase the impurities including in the slag. The pieces of the steel with different carbon contents are heated in the carburizing or decarburizing environment, termed jigane-oroshi. This process is carried out in the furnace burnt by charcoal and ash of rice straws with the blowing air sent by fuigo (blowers). Decarburization occurs in the part closed to the blower, while CO2 gas accelerates the sintering on the upper parts.

Forging process is followed to obtain a block, where about ten to fifteen rounds folding called orikaeshi are repeated to get laminated materials with approximately 1,000 (=210) to 30,000 (=215) layers called hada. The characteristic pattern of the laminated layers depending on the way of smiths is visible on the surface of the sword, some of which are depicted in Fig.4.

Fig.4 Hada, weld patterns by forging with hanmon, boundary of blade.

Such bonding of each layers during orikaesi and welding process is enhanced by the mechanism of so called mechanical alloying, for which so clean surface of the layers are necessary. This is achieved by dispersing impurities such as oxides and so on with sparks by hammering. The weight of the block decreases during the process to 700-1000g in the final shape of the Japanese sword being almost one tenth of initial weight.

A bar of shingane (core steel) with low carbon content is wrapped by kawagane or hagane (skin steel) with high carbon for which the tamahagane steel is normally used (see the cross sectional views in Fig.2). This process is called tsukurikomi, while similarity is seen in European swords. This combination of combination of two or three kinds of different steels with different carbon content induces the characteristic property of the sword with sharp blade with enough ductility as a whole for bending moment during cutting operation of obstacles. Such combination of different kinds of steel results in the nonuniform distribution of carbon in the cross section.

After rough shaping followed by grinding by the smith himself, the sword is transferred to the final process of yakiire (quenching or hardening), which is the main topics of numerical simulation in the following sections.

Before quenching or hardening, a kind of clay, yakiba-tsuchi, mixed by charcoal powder and so on is coated on the surface of the blade to control the heat transfer intensity to be discussed in next section (see Fig.5).

Fig.5 Clay coating technique

Most interesting situation is that the coated clay is thick on the ridge while thin on the blade part, which leads to increase the cooling rate of blade part and so to deepen hardening depth. This clay coating technique is employed for most blades as well as swords, but is probably unique in Japan.

Finally the quenching operation of the sword heated up to 800-850°C into water is carried out. (The temperature of heated sword and cooling water depends on the school of smiths and the material property as well as the dimension of the sword.)

During the quenching process, a white hard part with martensite structure is induced near the blade, while other shining part remains pearlite and ferrite structures. The border of the parts is called hamon. Here, wavy or zigzag pattern of the hamon is realized by cutting the clay by a spatulas.

5. Brief Summary of Metallo-Thermo- Mechanics and Developed CAE Sysytem "HEARTS"

In the course of quenching of the sword, or machine parts in general, incorporated with phase transformation, fields of metallic structure, temperature and stress/deformation are coupled each other as schematically illustrated in the diagram of Fig.6(19).

Fig.6 Coupling among metallic structures, temperature and mechanical fields in the course heat treating process.

The authors investigated the mechanics relevant to describing such three coupled fields for almost 30 years, and recently try to develop the data base of meny kinds of materials. Each field is to be described by the coupled fundamental equations of

a) Kinetics of phase transformation,

b) Heat conduction equation, and

c) A set of constitutive equation

combined with kinematic relation and equation of motion, which are reported elsewhere(19-22). Based on the theory, the author developed a finite element CAE code 'HEARTS' by for heat treatment(21-22). which are now used world widely. The motivation of the author to devote himself to develop the code rather comes from the hearty dream to simulate the coupled metallo-thermo-mechanical behavior of the Japanese sword.

Finite element scheme is applied to the fundamental equations developed above, and the version 2.0 of 'HEARTS' approximately with 35,000 steps consisted of 250 subroutines in several levels is coded by FORTRAN 77.

6. Identification of Heat Transfer Characteristics Depending on Clay Pasting

Before quenching the Japanese sword into water, the yakiba-tsuchi clay is coated on the surface as shown in Fig.5 to control the cooling condition of the surface of the steel. This kind of process to accelerate the cooling rate had been known by the sword smith since the method of manufacturing Japanese sword was established in 5 or 6 century, and is also applied to harden the blade of knives and other cutting tools. The author does not know how is in other countries.

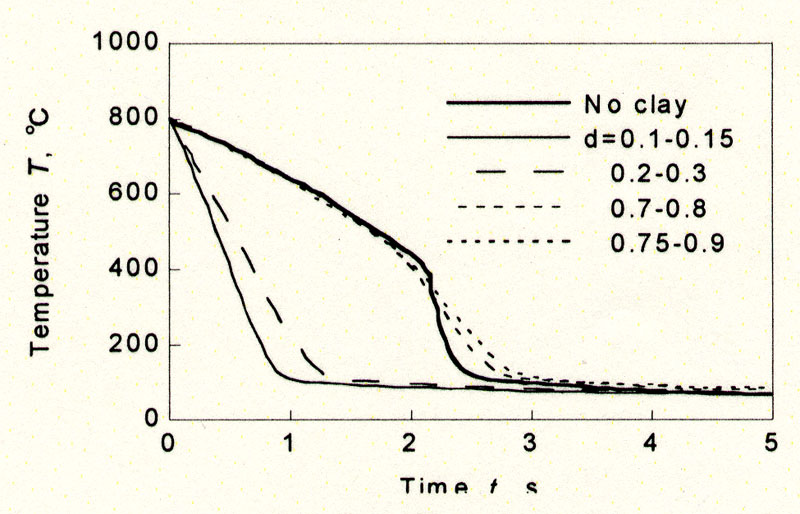

Since the temperature distribution is to be calculated in the body of the sword, it is necessary to identify the relative heat transfer coefficient on the metal surface as the function of the thickness of the clay. Series of experiments based on Japan Industrial Standard, JIS-K2242, were made to measure the cooling curve of a cylinder made of silver coated by the clay with different thickness. A thermocouple is mounted on the surface. The cylinder is heated up to 800°C by a reflection type electric furnace, and cooled in the water.

Obtained cooling curves are demonstrated in Fig.7(a) as the parameter of thickness of the pasted clay(7). It is so interesting that the curves for thick clay (t=0.7-0.8 and 0.75-0.9mm) show typical mode with moderate cooling rate due to film boiling followed by severe cooling stage by nuclear boiling, the shape of which are similar to the case without the clay. When the thickness is small (t=0.1-0.15 and 0.2-0.3mm), on the other hand, no film boiling stage is observed, which means that the cylinder is cooled severely from the beginning. This is also confirmed by the observation of bubble nucleation by video camera. Inverse calculation is carried out by perturbation method to identify the heat transfer coefficient on the surface of the cylinder.

It is a paradox to be noted from Fig.7(b) that the efficient in the case with thin clay gives higher value than without clay during 800-400°C being most important temperature range for quenching. This data will be employed as the boundary condition when solving the coupled heat conduction equation.

|

|

(a) Cooling curves.

| (b) Identified Heat transfer coefficient.

|

Fig.7 Cooling curves depending on coated clay thickness.

7. Simulated Results of Quenching Process

7.1 Sword treated and the condition of simulation

The sword treated here is 600 mm in length with 7 mm in maximum width, which is a model of a classical sword made in Houki region. Three dimensional finite element mesh division of the sword is represented in Fig.8, where the division is made for a half part in the width direction due to symmetry, and Fig.(a) and (b) respectively denotes the whole region and the enlarged part near kissaki, or tip.

|

(a) Entire region.

|

|

(b) Near the tip.

|

Fig.8 Finite element division of the sword.

Total number of the elements is 828, and that of the nodes is 1230. This model is supposed to consist of two regions, core steel with 0.2% carbon content and skin steel with 0.65%C to which different material data are applied.

To differentiate the relative heat transfer coefficient depending on the thickness of the yakibatsuchi clay, the surface of the sword is divided into two layers with different value as are evaluated by use if the cooling curves, also depending on temperature.

The sword is uniformly heated up to 850°C at which temperature the whole region is changed into austenitic structure, and the sword is quenched into the water of 40°C.

7.2 Variation of temperature, metallic structures, and associated deformation

Figure 9 demonstrates the temperature distribution of the surface of the sword with successive time from the beginning of the quenching, and the mode of deformation is also depicted in the figure. The part of blade near the blade with thin thickness shrinks due to thermal contraction by severe cooing, which leads to the bending to the downward termed as gyaku-sori or reverse bending at t=1s as is shown in Fig.(b).

Fig.9 Successive variation of deformation associated with temperature.

Figure 10 shows the change in calculated distribution of martensite and pearlite fraction associated with deformation in comparison to the initial shape. When martensitic transformation starts to occur in that part, however, normal bending called sori to the upper direction is observed due to the volumetric dilatation by martensite formation (see Fig.(c)). Gyaku-sori again appears at t=3-4s, because of the pearlite transformation in the part of ridge. In the successive stage of cooling, hot ridge side shrinks gradually because of thermal contraction, and finally, the normal bending can be obtained. Thus simulated deformation gives the good agreement with the actual bending mode of sori.

Fig.10 Successive change in fraction of structures.

7.3 Stress distribution and residual stresses.

Stress distribution in the longitudinal direction in the course of quenching is represented in Fig.11. This data of simulated residual stresses after complete cooling are compared with measured data by X-ray diffraction technique, and satisfactory coincidence is obtained.

Fig.11 Variation of longitudinal stress distribution.

It is also noted that the maximum stress near the tip of the sword during quenching reaches the fracture stress, which sometimes leads to cracking or breakage of the sword during the operation. Variation of stress distribution during quenching.

8. Concluding Remarks

Procedure of preparing the traditional Japanese steel, tamahagane by the tatara system, followed by the method of manufacturing the Japanese sword is summarized from the scientific point of view. Here, the author's opinion related to the steel and sword making process in foreign countries is stated.

As an example of the application of the simulation of quenching processes, a Japanese sword is focussed, and the change in temperature, metallic structure and stress/deformation are calculated. The results reveal to represent such real situations. The discussion from the viewpoints of metallurgy and mechanics are carried out in each section of preparing Japanese steel and manufacturing the sword, especially on the effect of pasted clay.

In conclusion, the technology surviving for over thousand years is really consistent with the modern science and technology.

References

- K. Tawara, Scientific Research on Japanese Swords (in Japanese), Hitachi-hyoronsha, Tokyo, 1953.

- B.C. Bain, Nippon-to, An Introduction of Old Swords of Japan, J. Iron and Steel Institute of Japan(1962) 265-282.

- T. Suzuki, Traditional Technology of Making Japanese Swords (in Japanese), Rikougaku-sha, Tokyo, 1994.

- K. Ishikawa, Nippon-Toh (Japanese Sword) --- High-Technology Threading Through History, Lecture Note, Rochester Institute of Technology, Rochester (1993).

- H. Fujiwara and T. Hanabusa, Scientific research of Japanese sword - its curvature (sori) and residual Stresses (in Japanese), Research Report, Faculty of Eng., Tokushima Univ., (1993) 1.

- H. Fujiwara, T. Hanabusa and K. Tanaka, Scientific research of Japanese sword - its curvature (sori) and residual stresses, Proc. 3rd Int. Conf.Residual Stresses, 2 (1991) 1537-1542.

- T. Uehara and T. Inoue, Quenching process simulation of Japanese sword covered with Clay (in Japanese ), J. Soc. Mater. Sci., Japan, 44 (1995) 309-315.

- T. Inoue, Japanese sword in science and technology-Computer simulation of quenching process (in Japanese), Boundary, 11 (1995) 36-41.

- T. Inoue, The Japanese sword --- Material, forging and simulation of quenching (in Japanese), Materia, 135 (1996) 174-178.

- T. Inoue, The Japanese sword ---- the material, manufacturing and computer simulation of quenching process, Materials Science Research International, 3-4, (1997), 193-203.

- T. Inoue, The Japanese Sword ---- the Material, Manufacturing and Computer Simulation of Quenching Process, 2002 Journal of the South African Arms and Armour Society, 2002, pp.108-142

- T. Inoue, Japanese Sword in Comparison with Others, Proceedings of 8th International Conference on Mechanical Behaviour of Materials, Victoria, Canada, May 16-21, pp.458-468

- A.R. Williams, Seven swords of the renaissance from an analytical point of view, Glaudius 14 (1978) pp.97-127

- Committee on Restoration Project of tatara Steel-making System, Restoration of tatara Steelmaking Process and the Blister Steel (in Japanese), ISIJ-Special Report No. 9 (1970).

- Y. Matsushita, Restoration off the "tatara" ironmaking process, an ancient ironmaking process of Japan, Proc. Int. Conf. Science and Technology of Iron and Steel, Trans. ISIJ,11 (1971) 212- 218.

- J. Kozuka, "tatara" process --- A pig iron- and steel making process, transmitted from ancient times in Japan, Trans. ISIJ,8 (1968) 36-47.

- K. Kubota, Japan's original steel making and its development under the influence offoreign technique, Coll. Int. Inst. CNRS, No.538 (1970) 577-591.

- K. Horikawa, The ancient nails of "Horyuji" temple and the restoration of the "tatara" ironmaking process, Bull. Metals Museum,12 (1982) 29-37.

- T. Inoue, S. Nagaki, T. Kishino and M. Monkawa, Description of Transformation Kinetics, Heat Conduction and Elastic-plastic Stresses in the Course of Quenching and Tempering of Some Steels, Ing.-Archiv, 50(1981) 315-327.

- T. Inoue, Metallo-thermo-mechanical Coupling --- Application to the Analysis of Quenching, Welding and Continuous Casting Processes, Berg-und Hutten-mannische Monatshefte, 132 (1987) 63-71.

- T. Inoue, D.Y. Ju and K. Arimoto, Metallo- t thermo-mechanical Simulation of Quenching Process --- Theory, and Implementation of Computer Code "HEARTS", Proc. 1st Int. Conf. Quenching and Control of Distortion (1992) 205-212.

- T. Inoue and K. Arimoto, Development and Imple-mentation of CAE System "HEARTS" for Heat Treatment Simulation based on Metallo- thermo mechanics, J. Mater. Eng. and Perfor., ASM,6 (1997) 51-60.

|